Engineers Mobilise to Kazakhstan on FGP Project

Work has started on the commissioning of various explosion proof cranes supplied on the Tengiz Future Growth Project in Kazakhstan. JBC engineers will start work on the first phase of cranes scheduled to run through until June 2020.

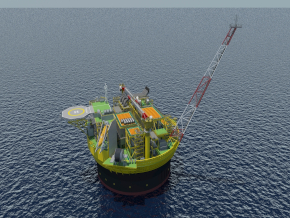

Shell Penguins FPSO Material Handling Package Award

Shell Penguins FPSO will extend the life of the Penguins Oil and Gas Field in the North Sea by 20 years. JBC received a PO from an engineering house in the Philippines for a material handling package that includes a range of spark-proof manual trolley hoists, davits, floor trolleys, beam clamps.